Constant Profile Carbide Tooling

Constant Profile Carbide Tooling

Meccanotecnica Veneta or MTV have partnered with Alouette Tool Co. to bring customized high quality precision carbide tooling to North America at competitive pricing. MTV provides specialized tooling for Aerospace, Automotive, Eyewear, Jewelry, Key Making, Medical and Watch Making industries – accomplishing each sector’s unique demands and specifications.

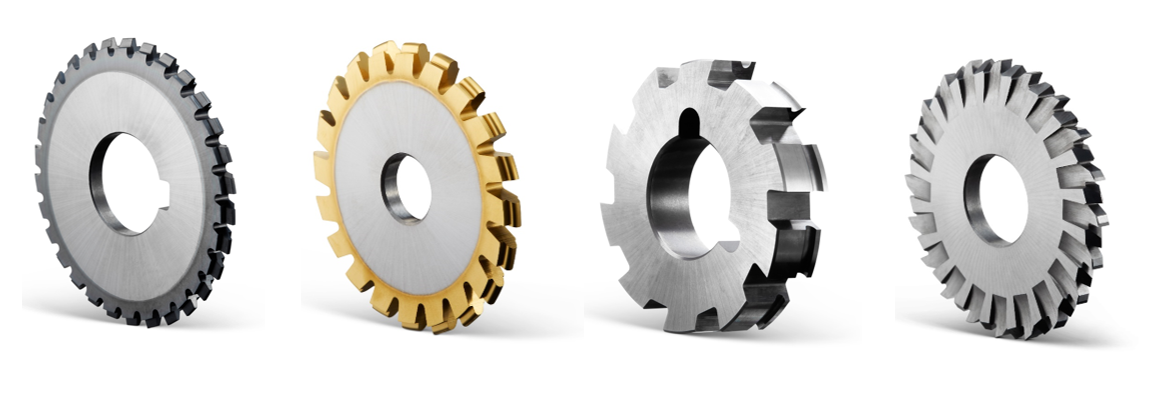

Products include Carbide Form Cutters, Milling Cutters, Circular Cutters, Micro Tools, Special Carbide End Mills and Twist Drills, and Standard Carbide Circular Saws. Learn more below.

Logarithmic Relief Grinding

MTV’s “logarithmic relief grinding”, also known as “constant profile” tooling, refers to the logarithmic fall-off on the back of the cutting edge of their circular tools. This guarantees the constancy of the rake and profile after the tooth’s face has been reground. This significantly helps tool life by allowing an increased number of regrindings.

When regrinding the face of the tooth and maintaining the exact same cutting angle as original, the rake and the profile remain unchanged. The tool’s output does not change and the profile is not deformed. The operation can be repeated as long as the tooth maintains its mechanical strength. The rake angle is always the same as the initial angle & the profile remains unchanged.

Circular Cutters are produced from 5 mm diameter up to 200 mm O.D. or 160mm for Profiled Circular Cutters with ability to apply coatings and suit ISO DIN or other standards.

Alouette Tool stocks Standardized Solid Carbide Saws in 15, 20, 25, 30, 40, and 50mm OD with widths of .10mm – 2.50mm – in .05mm or 2 thousandth increments – and can provide quotes for any radius or specialized cutters in 1-2 business days.

ISO Standard Medical & Dental Tooling

Patient safety is MTV’s top priority. Tools used in the medical & dental sector, which come into contact with tissues, even for a short time, need to guarantee cell compatibility. The hard metal corrosion-resistant quality of MTV tooling is verified in vitro cytotoxicity tests according to DIN EN ISO 10993-5 to guarantee maximum safety and reliability. MTV is also ISO certified 9001 – 14001 – 45001.

Extreme hardness and breakage resistance for maximum precision work and a long service life.

Aerospace & Automotive

MTV is ISO 9001:2015 certified. Thanks to highly specialised technical qualification and the latest generation machinery, MTV manufactures and supplies mechanical parts for assembly units for various aerospace and automotive applications. Designing in close collaboration with the customer the most suitable chip solutions on a case-by-case basis.

Our impeccable service, vast technical know-how, and constant attention to the development of customised solutions make MTV the perfect partner for any project.

- Precision milling, turning, and grinding

- Quality control of mechanical parts

- Wear resistance