Solutions for the challenge ahead: unleaded material

As the last producer of leaded steel in the US has closed, and as Congress catches up to Europe’s tough regulation on leaded brass & steel, Swiss CNC Shops will face new challenges in machining unleaded materials in 2024. Alouette Tool has the solutions.

Thanks to its good electrical conductivity combined with mechanical stability and corrosion resistance, brass is widely used. Reducing the lead percentage in the existing alloys is significantly impairing their machinability, confronting the manufacturers to new challenges. The lead in the brass alloys ensured good chip breakage and had a slight lubricating effect. Friction was reduced, resulting in lower heat generation in the machining process.

Without lead, brass develops long, stringy, ribbon like chips, resulting in machinists frequently having to stop their machine and clean the area. It also is tougher material to machine. More time spent cleaning out chips and changing worn tools leads to longer production times (especially for newer machinists on the C Shift) and a vast decrease in process reliability.

A preemptive act on the change in regulation, both of our Swiss partner’s Bimu SA and Ifanger AG have developed new geometries for machining unleaded brass to combat this new challenge in Europe (and soon the United States).

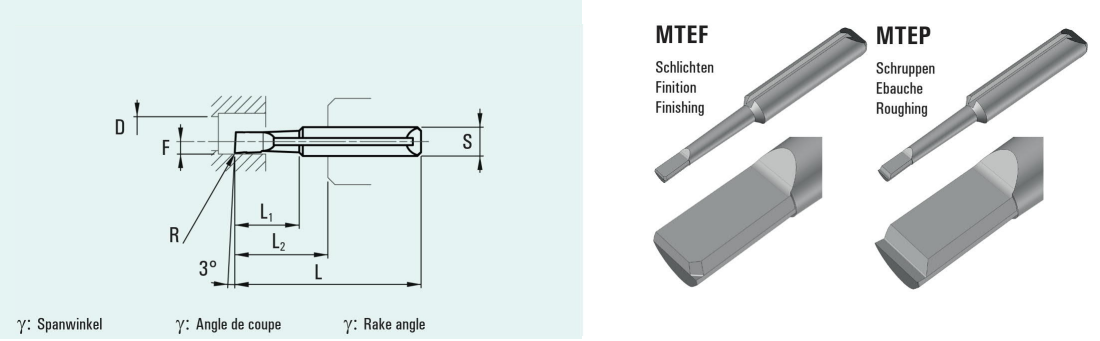

Ifanger’s New Geometries Designed for Unleaded Brass: MTEF & MTEP

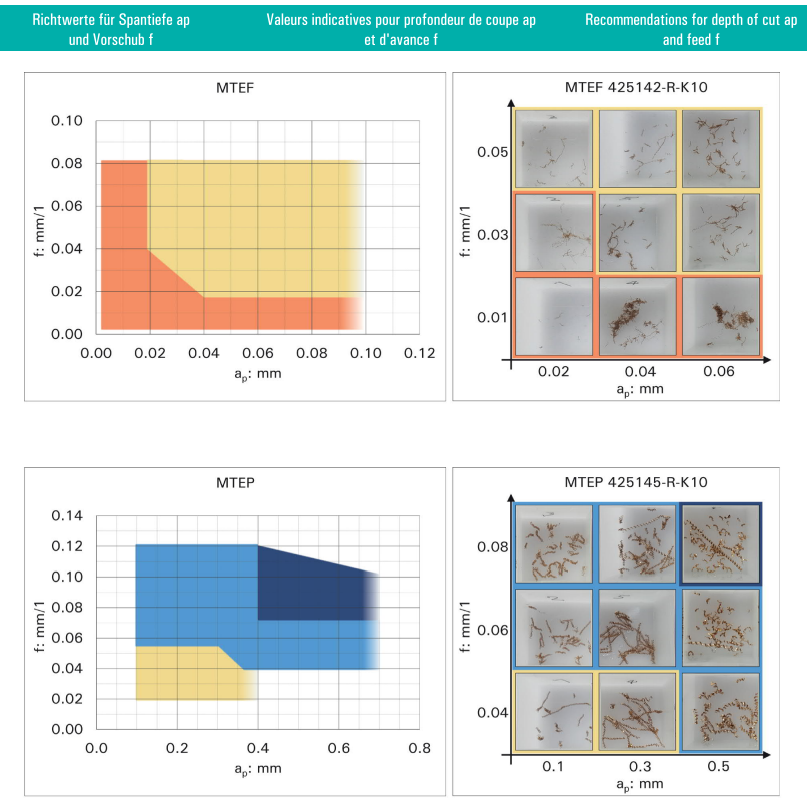

The MTEF (Finishing) and MTEP (Roughing) Boring tools bring solutions to unleaded brass. These new geometries have tough chip breakers that rid of the long ribbon like chips filling up the chambers of Swiss Machines. Through thorough testing, Ifanger has also developed a diagram that allows engineers and operators to pick their ideal chip size and surface roughness – and run the suggested feed and depth provided. Through customer feedback, they found that these new geometries have also proven great for breaking chips of aluminum and titanium.

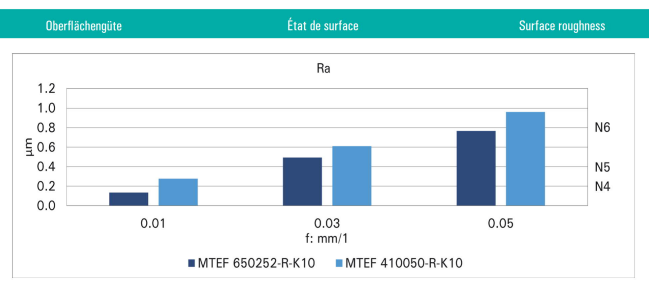

BIMU’s New Turning Insert Geometries and Coating for Unleaded Brass

BIMU’s selection of geometries with varying chip breakers and radius’ shown left are particularly suitable for machining lead-free brass.

BI-110 Coating is AlTiCrN-based with a very smooth surface finish, with high heat resistance and high wear resistance resulting in longer tool life.

Also suitable for machining pure copper, CuBe, CoCr and aluminium.

In addition, the «universal» BI-90 coating (AlTiN-based) perfectly complements the 060RZ geometry for this type of machining. BI-90 coating has high oxidation and heat resistance, making a good pair for machining of steel and stainless steel as well.

Click here for BIMU’s 040 Line Catalog

Click here for BIMU’s VPGT Catalog

As Congress catches up to Europe’s tough regulation, the demand for unleaded brass and steel will become more apparent. There is no avoiding this change, but a successful change is possible with the knowledge and awareness of turning tools suited for this challenge.

Thanks to the foresight of our Swiss partners, when the time comes we have you covered!

For any questions, or to learn more, please call us today or send us an email at info@alouettetoolco.com

Published by Shawn Brogan

Vice President of Business Development

Email: shawn@alouettetoolco.com

Phone: +1-585-388-1240 Ext. 103