Thread Rolling

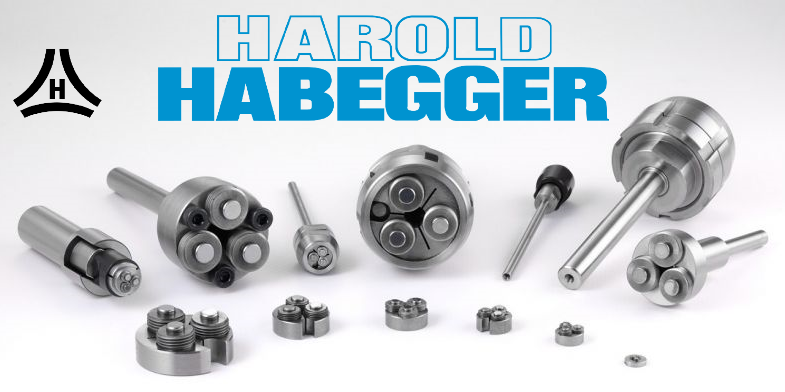

Habegger SA

Through our partner Habegger SA, Alouette offers Adjustable Thread Rolling Dies, Knurling Dies, and Burnishing Dies with their respective holders for both CNC & Cam machines. We also offer Habegger Revolving Guide Bushing and Guide Bushing repair kits.

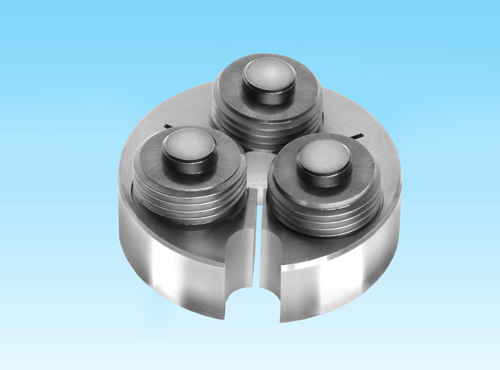

Thread Rolling Dies

Single point threading requires multiple passes and longer machining times.

With Habegger Thread Roll Dies, simply feed on and off with a G32 code and

you have a perfectly threaded part, drastically reducing production time.

Thread diameters from 0.30mm to 14.00 mm

UN Series from #000-120 to 9/16”-32

Pitch from 0.08 to 1.25 mm, or 20 TPI to 120 TPI

Dies are available in LH for most all sizes

Non-adjustable dies also available for 0.50mm and smaller

Advantages of thread rolling:

- Better thread quality

- High machining regularity

- Increased thread resistance

- Reduced breaking points

- Better surface values on the thread flanks and on the thread root

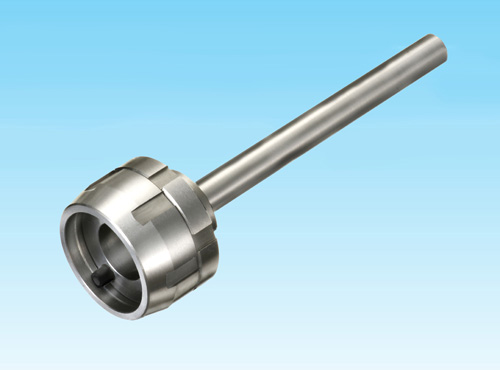

Compensating Holder

Fixed Holder

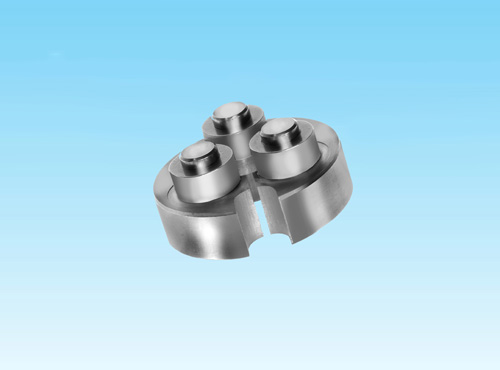

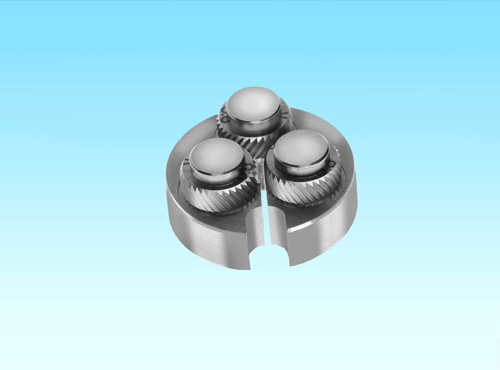

Knurling Dies

Diameter after knurling: from 0.60 to 14.20 mm

Pitch from 0.13 to 1.00 mm according to diameter

Sizing of knurling dies are available in tenths of a millimeter.

Advantages of Knurling Dies:

- No untrue workpiece after the knurling operation

- No radial effort exerted on the collet or guide bushing

- Possibility to knurl diameters smaller than 1 mm

- Better knurling quality

Knurling dies are used for straight or crossed knurling (30° or 45°). They work without radial effort. No pressure is exerted on the workpiece, even with the smallest diameters. The three knurls forming the teeth assure a high quality of the job and the long life of the die.

Diameter before knurling increases by 25 to 35% of the pitch value, according to the machined material. These values are in direct relation with the material resistance.

Burnishing Dies

Diameter after burnishing: from 0.50 to 12.40 mm

The sizes of the burnishing dies are available per tenths of a millimeter

The burnishing operation improves the surface finish, but does not influence the diameter

Advantages of Knurling Dies:

- Excellent surface finish

- No radial effort exerted on the collet or guide bush

- Possibility to burnish diameters smaller than 1 mm.

The peripherical speed of the workpiece must be about 20 meters/minute. The speed is lower when the material to be smoothed is very hard. The indicative value for the feed is 0.2 to 0.5 mm/revolution.